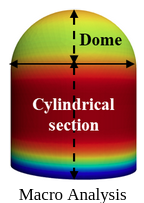

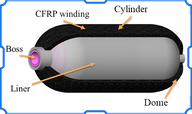

Geometrical Parameters

- Liner and Boss geometry

- Manufacturing & assembly

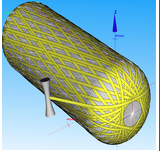

- Parametric Modelling

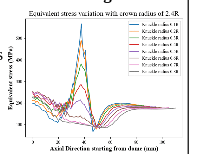

CAM Analysis

- Winding angle

- Friction factor limit

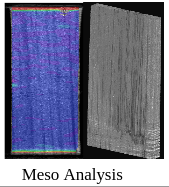

- Fiber coverage area

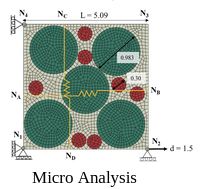

- Number of cycles

Manufacturing Process

- Fiber tension

- Winding speed

- Mandrel & spool

- Ply sequence